Installation & Maintenance

Sort

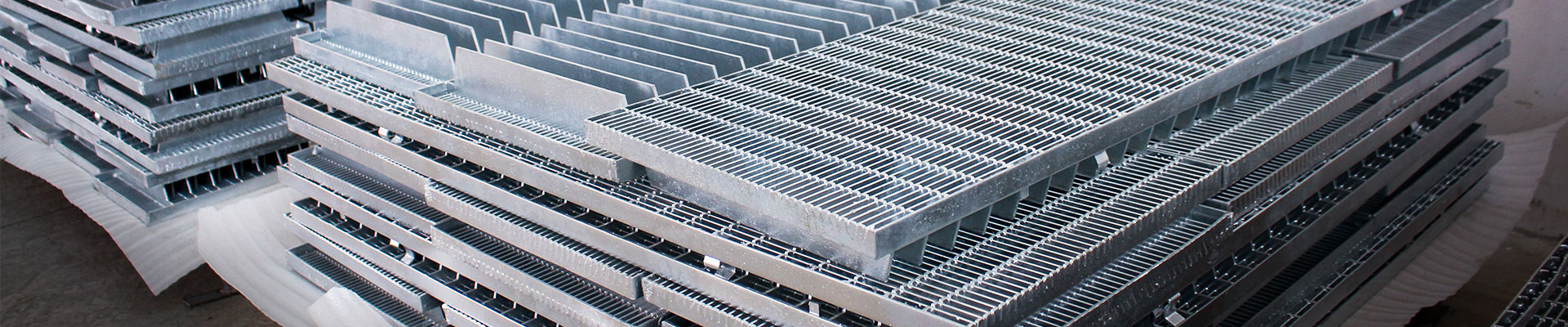

Installation & MaintenanceBefore construction, collect and complete the drawings and related specifications, specifications and commodity certificates, and do a good job in the inspection work. On-site factories and workers must do a good job in the disclosure of drawings and skills. Site preparation: (1) Determine the stencil stacking site and do a good job of unloading. (2) Check the device orientation, beam spacing, and steel grating errors, and determine the starting device baseline (side beam centerline). (3) Contact for crane leasing matters. Preparation of various resources: (1) Manual dispensing plan device: 50 people, welders, 4 people, electrician: 2 (2) Mechanical equipment dispensing plan: 4 forklifts, lifting device directional field construction corresponding () 4 sets, electric welding machine: 5 sets, device: 20 sets of pedestrian propulsion, 12 sets of quality assurance measures (1) Requirements 1) Bearing flat steel: It can be made of Q235 steel of GB/T700 B. The flat steel used in the steel grating can be hot-rolled flat steel, I-beam, or longitudinal shearing of hot-rolled or cold-rolled steel strips. 2) The horizontal steel bar shall be made of the same material as the load-bearing flat steel, and shall comply with the relevant specifications and regulations. 3) The end plate (edge-wrapped version) should be made of the same material as the flat steel, and should comply with the relevant specifications. 4) Hot-dip galvanizing is adopted for the appearance of steel mesh panels, and the level of galvanized components shall comply with GB/T13912-2002 after other requirements (2) Key parts and process control 1) Raw materials and semi-finished products, all raw materials and semi-finished products must be in accordance with the specifications Inspection and identification. It is strictly forbidden to use raw materials and semi-finished products that have not been inspected and qualified for engineering. 2) Engineering replacement inspection: The appearance of the steel mesh is hot-dip galvanized, and the edges are wrapped after treatment. However, the components and requirements after galvanizing should also comply with the provisions of GB/T13912-2002. Before the equipment, the previous process must be checked and reviewed, and the corresponding records must be made. 3) Channel steel grille device: ensure a reasonable gap, a smooth appearance, and a height difference of no more than 3mm. 4) Fastening: Review planning requirements and specification rules for the tightness of all bolted fasteners. The overlap between the steel grating and the steel beam should not be less than 25mm. 5) When the construction team has not completed the process, the quality inspector and the receiving team must conduct self-inspection and account check on the process. After passing the test, the next process can be carried out only after being signed by the technical director of the project, and the inspection results shall be recorded on the record. 6) Material requirements: steel grating combined national standard and planning requirements: the allowable error of length is -5mm, the allowable error of width is 5mm, the allowable error of diagonal line is not more than 5mm, and the longitudinal deflection t plate of steel grating should not be greater than 4mm. (4) Packaging 1) The packaging shall consist of symbols and quality certificates. The steel grating is packed with steel strips, each bundle of 25 steel gratings weighs about 2 tons. 2) Quality certification documents: The commodity quality certification documents should indicate the standard number of the commodity, and indicate the steel number, model standard, appearance processing status, appearance and functional view results, and the quality certification document should be the commodity packing list. 5) Quality inspection: in line with YB/T4001.1-2007 "Steel Manufacturing Specifications and Quality Inspection Specifications".

Provide you with professional solutions

24/7 before-sales and after-sales services

Comprehensive technical support