Installation & Maintenance

Sort

Installation & MaintenanceAccording to its practical application, steel grating can be installed and fixed in many ways. Typically, welding installation, fastener fixing and angle steel fixing are three methods we commonly used for steel grating installation. You can choose a proper installation method suitable for your application.

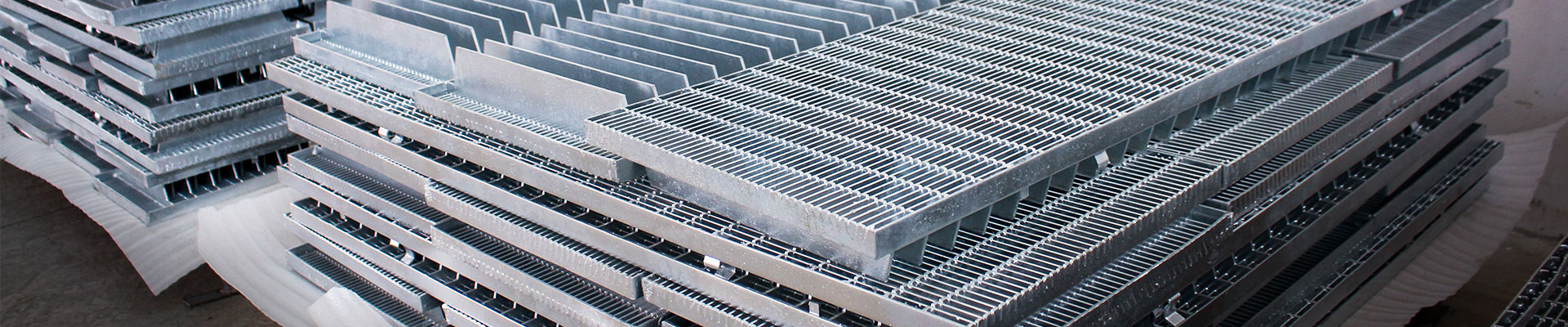

Before installing the steel gratings, please read the layout drawings and packing list carefully. Unpack the packaging box as required to avoid improper unpacking resulting in a field mess and reducing the work efficiency.

When the unpacking and reading is completed, please place steel gratings in their corresponding locations as required by layout drawings or their code number.

Installation clearance: The installation clearance between steel gratings shall fall within 5–10 mm for facilitating field installation and fine-tuning.

Description

Welding installation refers to the method of fixing steel gratings by welding. It is suitable for steel gratings require a permanent fixing. For the purpose of permanent fixing, steel gratings are welded under the supporting steel bar to form a permanent connection. It is characterized by simple installation, solid structure and reasonable price.

Installation Steps

Paint, rust, oil, water and other dirt must be removed from the surfaces of supporting steels and steel gratings before welding.

Sequence welding is adopted. Welding is generally performed at four corners of the steel grating. If the steel grating is subject to continuous heavy loads, additional welding points shall be added to strengthen its welding firmness.

When the welding is completed, anti-rust paint is manually sprayed on the weld joints to protect the surface of the steel grating from rusting.

Provide you with professional solutions

24/7 before-sales and after-sales services

Comprehensive technical support