Installation & Maintenance

Sort

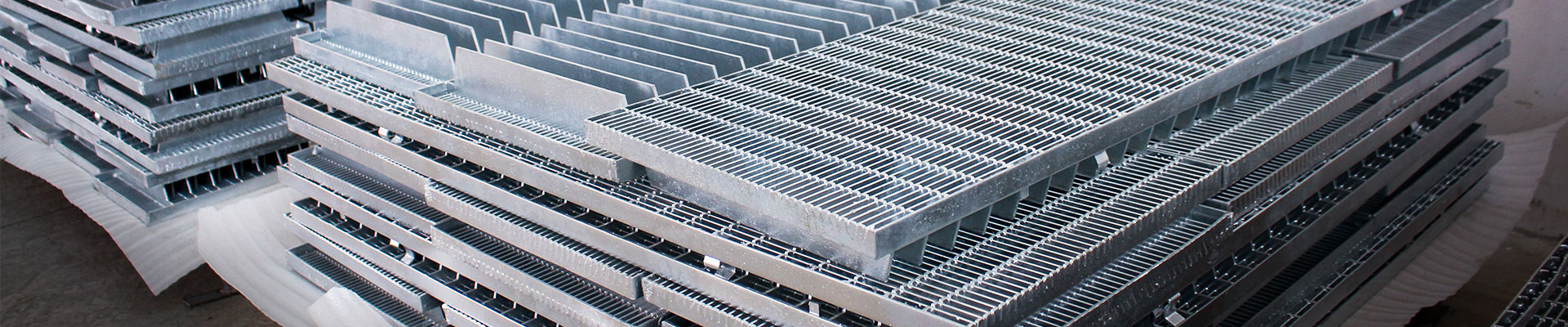

Installation & MaintenanceThe structure of the multi-layer steel frame of the steel grating frame considers the process requirements and land saving. A large number of vibration equipment are erected on the steel grating floor. These equipments often have a large self-weight and are excited under normal working conditions. The vibration frequency is generally between 10-25Hz, which is a low frequency vibration. It is very easy to generate low-frequency resonance with the floor covered with steel grating, resulting in the problem of abnormal floor vibration.

Reasons for abnormal vibration of steel grating frame floor

1. The process requires large openings on the floor. In order to reduce the ash load on the floor, steel gratings are often laid, resulting in low flexural rigidity of the floor slab, resulting in a reduction in the vertical natural vibration frequency of the floor slab. , which is close to the excitation frequency of the vibrating equipment, forming resonance.

2. The natural vibration frequency of the laid steel grating itself is low. Even if the resonance between the steel beam and the vibration equipment can be avoided, the vibration response will be amplified during the process of 0 vibration transmitted to the steel grating through the steel beam, resulting in the failure of the floor. Abnormal vibration.

3. Steel gratings and steel beams are often welded rigidly, which is not conducive to vibration isolation.

The steel grating frame floor generates strong vibration due to equipment excitation, which seriously affects the personal health of the plant staff, and the excessive amplitude poses a hidden danger to the safety of the plant structure. The vibration reduction of the steel grating frame structure reduces the vibration of the steel grating floor to the allowable range and reduces the floor vibration.

Several ways to reduce vibration

1. Increase the steel grating floor rigidity, so that the rotation frequency of the equipment falls in the resonance front area or resonance gap area of the structural components. There are many ways to increase floor stiffness. The stress state of the floor beams is changed by adding vertical columns on the floor. The method of adding small beams on the existing structure reduces the calculation span of the floor slab, and for the beams with insufficient vertical stiffness, the method of adding steel beams at the lower flange increases the beam height and thus increases the vertical stiffness of the beams. The rigidity of the floor is increased by adding a superimposed layer of 50mm thick concrete crushed stone and steel mesh on the basis of the original floor structure

2. Take vibration isolation measures for the equipment, that is, set a rubber or spring vibration isolator between the machine base and the supporting structure.

3. Adjust the excitation frequency of the equipment so that the operating frequency of the equipment avoids the natural vibration frequency of the floor. Through the method of speed regulation and vibration avoidance, the speed of the machine is adjusted to achieve the purpose of reducing the working frequency of the vibration equipment. However, this method is often not adopted because the adjustment operation frequency of the equipment will also affect the production efficiency of the equipment.

4. The finite element calculation method and subspace iteration method are used to analyze the dynamic response of the floor when the equipment with vibration damping pads is vibrated, and the method of how to choose the vibration damping pads for different structures and dynamic equipment is proposed. The multi-storey factory building exerts a control force on the vibration damping body, and the control force can play a damping role and absorb the energy of the vibration system, thereby reducing the vibration response of the vibration body. The most widely used of these are tuned mass dampers, also known as TMD systems.

Provide you with professional solutions

24/7 before-sales and after-sales services

Comprehensive technical support