Company news

Sort

Company newsWhat are the disadvantages of non-galvanized treatment of steel grating surface?

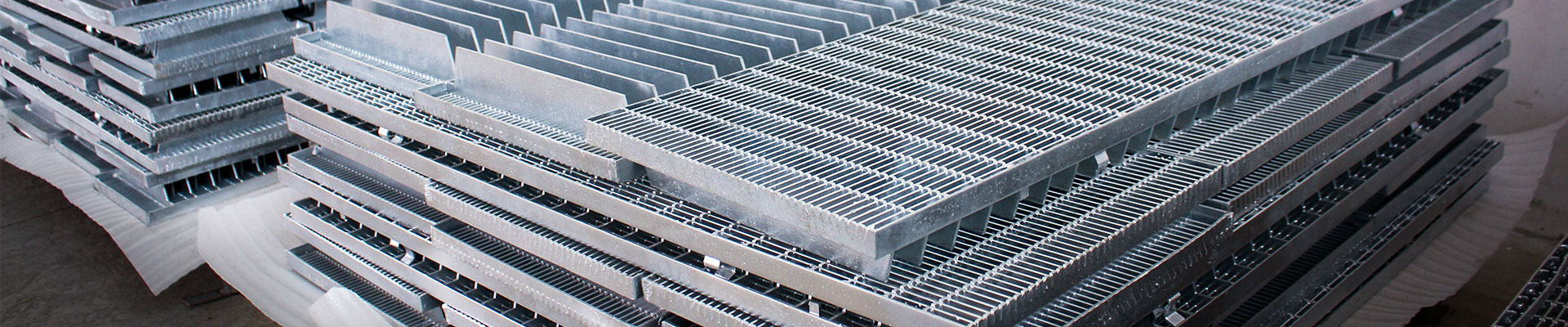

At present, users of steel grating require that the surface is not galvanized. The grating is a kind of steel product with a square lattice in the middle, which is cross-arranged with flat steel according to a certain distance and horizontal bars, and is welded by a pressure welding machine or manually. The steel grating is mainly used as a gutter cover. , Steel structure platform plates, steel ladder treads, etc. The cross bar is generally made of twisted square steel. Steel grating is an open steel member that is orthogonally combined with load-bearing flat steel and cross bars according to a certain interval, and is fixed by welding or press locking; cross bars are generally made of twisted square steel, but also round steel. Or flat steel, the material is divided into carbon steel and stainless steel. Steel grating is generally made of carbon steel, and the surface is hot-dip galvanized, which can prevent oxidation. Can also be made of stainless steel. Steel grating has the properties of ventilation, lighting, heat dissipation, anti-skid, explosion-proof and so on. Hot-dip galvanized steel grating is the most commonly used surface treatment method for steel grating. Finished steel grating immersed in a zinc bath. So what is the difference between galvanized steel grating and non-galvanized steel grating? Is it correct that galvanized steel grating is not galvanized?

First of all, it should be noted that after the steel plate is galvanized, the anti-corrosion ability is improved. The steel mesh itself has the characteristics of high strength and high bearing capacity, but the corrosion resistance is average, but after galvanizing, the corrosion resistance is enhanced, and it can be used in highly corrosive chemical plants.

The second anti-skid ability and drainage ability can be improved, and the surface of the steel grating can be galvanized without generating a large amount of waste, so that the drainage can be carried out with the gutter cover.

The third hot-dip galvanized steel grating is more beautiful and easy to clean. Galvanized steel grating is bright and easy to clean, so it is often used as a ceiling.

Therefore, the overall performance of galvanized steel grating is better than that of untreated steel grating. Users can consider it and you won't be disappointed.

Provide you with professional solutions

24/7 before-sales and after-sales services

Comprehensive technical support